About Prototeque: Your One-Stop Solution For Precision Manufacturing

Founded in 2014 by an industry veteran with over 20 years of mechanical engineering expertise, Prototeque has rapidly emerged as a leading provider of comprehensive prototyping and manufacturing solutions. Our journey began in Dongguan, China, the heart of global manufacturing. With a modest 534 square meter facility and a dedicated team of 11 employees, we laid the foundation for our future growth.

Recognizing the transformative power of additive manufacturing, we invested in a state-of-the-art 3D printing facility in 2020. To further strengthen our value chain, we established a sheet metal fabrication factory in 2021. In 2022, we expanded our global footprint with a dedicated sales team. Today, Prototeque boasts a team of 213 professionals operating out of a 9000 square meter facility.

Our comprehensive services include:

- Rapid prototyping:Utilizing advanced technologies like 3D printing, CNC machining, and urethane casting to create functional prototypes quickly and efficiently.

- High-volume production: Leveraging state-of-the-art equipment, including CNC machining centers, laser cutting machines, and sheet metal fabrication presses, to deliver large quantities of precision parts.

- Custom manufacturing: Tailoring our services to meet your specific requirements, from complex assemblies to intricate components.

Our state-of-the-art equipment includes:

- CNC machining centers: 40 units.

- CNC turning centers: 31 units.

- Laser cutting machines: 3 units.

- Sheet metal fabrication presses: 6 units.

- 3D printers: 39 units

We are committed to delivering the highest quality products and services. Our rigorous quality control processes involve:

CMMs (Coordinate Measuring Machines)

Profile projectors

Various gauges and inspection tools

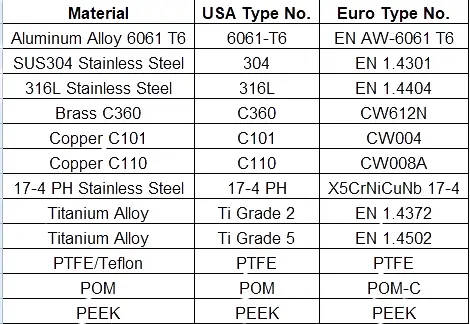

In-House Raw Materials for Fast Manufacturing & Prototyping

We have inventory of commonly used raw materials, which greatly shortens the production cycle to meet customer emergency needs. Some common material we often machine are listed in the following table

Advanced Sheet Metal Fabrication with 30kW Laser Cutting & CNC Bending

Prototeque’s state-of-the-art sheet metal fabrication workshop is equipped with advanced machinery to deliver exceptional metal components. Our capabilities include:

Laser Cutting: Precise cutting of various materials with our 3 laser cutting machines (3000W, 6000W, and 30,000W).

CNC Bending: Accurate bending of sheet metal with our fleet of 6 CNC bending machines.

We specialize in transforming sheet metal into functional and aesthetically pleasing parts, catering to a wide range of industries. Our commitment to quality and precision ensures your project is in capable hands.

Sheet Metal Fabrication Workshop

Prototeque’s state-of-the-art sheet metal fabrication workshop is equipped with advanced machinery to deliver exceptional metal components. Our capabilities include:

Laser Cutting: Precise cutting of various materials with our 3 laser cutting machines (3000W, 6000W, and 30,000W).

CNC Bending: Accurate bending of sheet metal with our fleet of 6 CNC bending machines.

We specialize in transforming sheet metal into functional and aesthetically pleasing parts, catering to a wide range of industries. Our commitment to quality and precision ensures your project is in capable hands.

High-Precision CNC Machining for Prototyping & Production

Prototeque’s state-of-the-art CNC machining workshop is equipped with an extensive array of high-precision machines to meet your most demanding prototyping and production requirements.

Our milling capabilities include:

25 advanced 3-axis CNC milling machines

15 versatile 5-axis CNC milling machines for complex geometries

For turning applications, we offer:

- 24 high-performance CNC turning centers

- 7 precision Swiss-type lathes for intricate components.

This robust infrastructure, combined with our skilled machinists, ensures exceptional quality, accuracy, and efficiency in every project.

Advanced 3D Printing with SLA, SLS & HP MJF

Prototeque is your premier destination for rapid prototyping and low-volume production. Our state-of-the-art workshop houses an extensive array of cutting-edge equipment, including:

20 SLA 3D printers

9 SLS 3D printers

10 HP MJF 3D printers

3 Urethane Casting machines

This robust infrastructure empowers us to deliver exceptional prototypes and functional parts with unmatched speed and precision. Whether you require complex geometries, durable materials, or fine surface finishes, our 3D printing and urethane casting capabilities exceed expectations.

3D Printing Workshop:

Prototeque is your premier destination for rapid prototyping and low-volume production. Our state-of-the-art workshop houses an extensive array of cutting-edge equipment, including:

20 SLA 3D printers

9 SLS 3D printers

10 HP MJF 3D printers

3 Urethane Casting machines

This robust infrastructure empowers us to deliver exceptional prototypes and functional parts with unmatched speed and precision. Whether you require complex geometries, durable materials, or fine surface finishes, our 3D printing and urethane casting capabilities exceed expectations.

Our Grinding & EDM Machining Services

Prototeque’s dedicated grinding workshop delivers exceptional surface finish and dimensional accuracy. Our advanced equipment includes:

- 5 precision grinding machines for precise surface finishing

- 2 EDM (Electrical Discharge Machining) machines for intricate shapes

- 3 EDW (Electro Discharge Wire Cutting) machines for complex contours

This powerful combination enables us to achieve tolerances as low as +/- 0.005mm and surface finishes of RA 0.4 or better. Whether it’s cylindrical, surface, or internal grinding, we have the expertise and technology to meet your exact specifications.

Rigorous Inspection Processes for Quality Assurance

Our advanced inspection room is equipped with cutting-edge metrology equipment to ensure precise and consistent quality.

Key inspection tools include:

- Coordinate Measuring Machine (CMM)

- Profile Projector

- Height Gauge

- Calipers

- Pin Gauge

- Block Gauges

- Thread Gauges

Our rigorous inspection process guarantees that both CNC machined parts and rapid prototypes meet the highest standards of accuracy and precision. Every dimension, feature, and tolerance is meticulously verified to ensure your complete satisfaction.

Prototeque Inspection Room

Our advanced inspection room is equipped with cutting-edge metrology equipment to ensure precise and consistent quality.

Key inspection tools include:

- Coordinate Measuring Machine (CMM)

- Profile Projector

- Height Gauge

- Calipers

- Pin Gauge

- Block Gauges

- Thread Gauges

Our rigorous inspection process guarantees that both CNC machined parts and rapid prototypes meet the highest standards of accuracy and precision. Every dimension, feature, and tolerance is meticulously verified to ensure your complete satisfaction.