Here’s All About Manufacturing of Brass, Benefits & Uses

Brass is an easily machined metal and antibacterial, so, it is highly valued. It is composed chiefly of copper and zinc and has a golden-yellow appearance. There are also higher copper content versions of this alloy, which will be a reddish color, known as ‘red brass’.

CNC Bronze Machining: Best Practices for High-Performance Components

Bronze CNC machining can be tricky. Blunting, overheating, and getting a smooth finish usually contribute to time wastage and unsatisfactory outcomes. These challenges can be caused by quality issues or cost drivers.

Copper 101 vs 110: Which One Is Right For Your Project?

Are you in doubt, about whether to choose copper 101 vs 110 for use in your CNC machining project? Since both types possess specific properties designed for a particular use.

Alloy Steel Vs Stainless Steel: Which One Is Right For Your CNC Machining Project?

Alloy Steel and stainless steel are prevalent CNC machining materials in the contemporary fabrication market. Typically, both are composed of iron and carbon used in construction and defense and often share similarities to each. Steel gives peculiar features in machined products like strength, durability, versatility, and easy fabrication. When it comes to steel classification, there […]

9 Major Differences Between Titanium Vs Stainless Steel

We always consider titanium stainless steel in capacitative use such as industrial, commercial, or even consumer products. Both titanium and stainless steel have significant features that expand their scope of applications in numerous industries. These industries can be aerospace and medical industries. Besides this, it is difficult for customers to choose between titanium and stainless […]

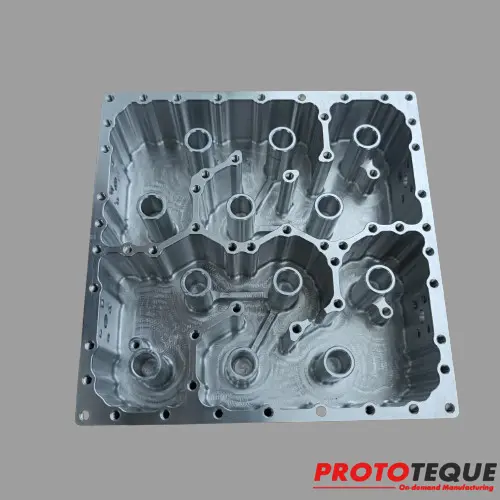

CNC Machining for Aluminum: A Quick Guide

CNC methods for machining aluminum components

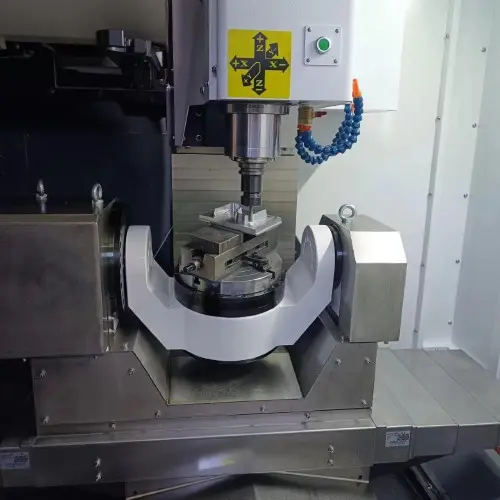

What is 5 Axis CNC Machining? 4 Basic Points You Should Know

5-axis CNC machining is an advanced manufacturing process featuring two rotary and three linear axes, enabling exceptional precision and flexibility. Unlike traditional 3-axis machines, 5-axis CNC machines can tilt and rotate the cutting tool or workpiece, allowing for complex shapes and designs. Key advantages include enhanced machining quality, reduced fixture usage, and streamlined production processes. These machines excel in various industries, from aerospace and automotive to medical and consumer electronics, delivering superior results and cost savings. Understanding 5-axis CNC machining’s long-term value is crucial for optimizing production efficiency and achieving high-quality outcomes.

From Simple to Complex: Unveiling the Power of Different CNC Turning Machines

CNC turning offers incredible versatility for creating precise cylindrical parts. But with an array of machines available, selecting the right one can be daunting. This guide explores four common CNC turning machines to empower your decision-making, and how Prototeque can be your perfect partner: Fixed Headstock CNC Lathe (Flat-Bed Lathe):The workhorse of CNC turning, this […]

Sinker EDM: The Machining Master for Hard and Intricate Parts

Electrical Discharge Machining (EDM), also known as spark machining or spark erosion, is a non-traditional machining process that utilizes controlled electrical sparks to erode material from a workpiece. This allows for the creation of intricate shapes and features in challenging materials, making Sinker EDM a valuable tool in various industries. When Does Sinker EDM Shine? […]

Reduce Costs, Boost Quality: How to Choose a Supplier for Project Success

Beyond Size and Equipment: Why a Technically Savvy Supplier Boss Matters As a sourcing engineer with 8 years of experience, I’ve seen countless buyers prioritize flashy factors when choosing suppliers: large scale, advanced equipment, impressive inspection capabilities. While these aspects hold some value, they often overshadow a crucial element – the technical background of the […]